Your risk assessment may identify the need for fire fighting equipment such as:

Your risk assessment may identify the need for fire fighting equipment such as:

• Portable fire extinguishers

• Fire blankets

• Fire buckets

• Hose reels

• Sprinkler systems

• Water mist systems

• Water spray systems

• Gaseous fixed fire extinguishing systems

• Foam systems

• Powder systems

• Kitchen fire suppression systems

• Facilities for use by fire fighters including fire mains,

fire fighting lifts and fire fighters switches for high voltage illuminated signs. The sections that follow will give more information about this equipment to help provide a basic understanding of its applications and use.

PORTABLE FIRE EXTINGUISHERS

Critical parts of UK fire legislation are the general fire precautions or fire safety measures that the responsible person will need to take to comply with the law.

Critical parts of UK fire legislation are the general fire precautions or fire safety measures that the responsible person will need to take to comply with the law.

Key measures of these general fire precautions can, in part, be met by the adequate provision of portable fire extinguishers, the application of a suitable system of maintenance and effective training in their use.

Portable fire extinguishers are able to control or extinguish small fires, preventing them from developing into big ones before Fire & Rescue Service arrive. Portable fire extinguishers are valuable in the early stages of fire because of their portability, immediate availability and easy use by one person.

People are not expected to deal with a large fire, since extinguishers are essentially first aid fire fighting appliances of a limited capacity. But their ability to help contain the spread of fire may be vital until the Fire & Rescue Service arrive.

The capability to contain and prevent the spread of small fires is an essential tool in meeting general fire precaution measures or fire safety measures required by law. Portable fire extinguishers can reduce the likelihood of the spread of fire on the premises and mitigate the effects of the fire on people, property and the environment.

Fire fighting equipment should be simple to use, essentially, a pull-pin, point and squeeze handle operation. This makes them easy for anyone to use. However, the usefulness of portable fire extinguishers depends on people knowing how to use them. All modern extinguishers have clear instructions on them. Where there are employees some, and preferably all, should be provided with formal training.

Various types of portable fire fighting equipment are available, ranging from the simple fire bucket with water or sand through to water-based extinguishers as well as foam, powder, CO2 and wet chemical extinguishers.

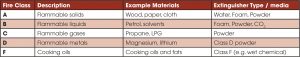

Guidance in BS 5306-8, the code of practice for fire extinguishing installations and equipment on premises, advises on the selection and installation of portable fire extinguishers. Recommendations are given on the type, quantity and rating of fire extinguishers that should be used and where they should be located such as on escape routes, stairwells, fire exits and corridors. This will ensure that the means of escape can be safely and effectively used at all times. The type of a fire extinguisher will be dictated by the fire class and this is defined in the table below. Fire Safety Legislation requires that fire safety equipment should be installed, commissioned and maintained by a competent person.

It is strongly recommended that installation, commissioning and maintenance of portable fire extinguishers be carried out by a BAFE SP101/ST104 certified company. This provides assurance that the service provider is competent.

Portable fire extinguishers form only part of building fire protection, and it should not be assumed that their provision removes the need for other protection.

HOSE REELS

Hose reels can be installed in all types of building, from factories and storage facilities to offices, shops and transport centres as well as schools, healthcare facilities, hotels, and prisons.

SPRINKLER AND OTHER WATER-BASED FIXED FIRE EXTINGUISHING SYSTEMS

Several water-based fixed fire extinguishing systems are available and these systems can be installed in many types of building. The type and size of system and the requirement for pumps and other equipment will be determined by the system designer. Sprinkler systems should be installed to EN 12845 by companies certified to either FIRAS or LPS 1048 third party certification schemes, which will prove their competence in this area.

Most sprinkler systems are installed for property protection but very often they play a part in an engineered fire safety solution for a building. Sprinkler systems can be installed in many types of building. The size of system and the requirement for pumps and other equipment will be determined by the system designer.

Several types of sprinkler system are available to suppress fires in ordinary combustibles:

The most common sprinkler system is a wet pipe installation in which the system is permanently charged with water under pressure.

Dry pipe systems are used where the system may experience low temperatures that would freeze the water.

Pre-action systems are similar to dry pipe systems where the system is maintained dry and water is allowed into the system following activation of a fire detector.

In deluge systems the pipework is empty and unpressurised, and in this case the nozzles are open (i.e. without heat sensitive elements). A separate fire detection system is used to activate deluge valves, allowing water to enter the piping system. Water flows from all nozzles simultaneously. These systems are used where rapid spread of fire is a concern.

Water spray fire protection systems are specialised versions of a deluge system; the piping and discharge nozzle spray patterns are designed to protect a uniquely configured hazard.

Water mist fire protection systems utilise the large surface area of very small droplets of water to rapidly absorb heat by generating steam. In addition, the steam reduces oxygen in the vicinity of the fire. Water mist systems may use nozzles with glass bulbs (like sprinklers) for fire suppression of limited amounts of ordinary combustibles, or may have open nozzles for fire extinguishment of flammable liquid fires.

GASEOUS FIXED FIRE EXTINGUISHING SYSTEMS

Three groups of gaseous fixed fire extinguishing systems are available:

- Inert gas systems

- Chemical gas systems

- CO2 systems

Gas extinguishing systems are normally computer rooms, IT server rooms, indoor transformers and switchgear; telecommunications, generators, engine enclosures, turbine enclosures, flammable liquid stores, archive storage areas, warehouse, cold stores and laboratories.

Inert gases and chemical gases, often referred to as clean agent systems have replaced halon 1301 as an extinguishing agent except for certain critical uses. Generally gaseous fire protection systems are operated by specific automatic fire detection systems in which detector provision and spacing is configured to give very early detection. Usually the activation of two detector heads is necessary to discharge the gas, (coincidence detection). A warning is normally given in the protected area before the gas discharges to allow personnel to leave the area. CO2 systems have been used for many years for industrial hazards, but used in occupied areas for safety reasons.

Gaseous extinguishing systems should be designed, installed and maintained to EN 15004, (inert and chemical gases) or BS 5306-4, (CO2) by companies certificated to either LPS 1204, SP 202 or SP 203-3 third party certification schemes, which prove their competence in this area.

OTHER FIXED FIRE EXTINGUISHING SYSTEMS

There are other fixed extinguishing systems that are available and will suit certain applications. Some of the most common systems are described below.

Foam systems are used for areas where flammable liquids and/or plastics are handled and stored. Foam forms a blanket over the surface of flammable liquids to extinguish the fire. Foam may also be used to enhance water mist and water spray systems. Typical applications include; flammable liquid hazards; storage tanks and bunds; warehousing (foam enhanced sprinklers); process areas (foam enhanced water spray); machinery; aircraft hangers and flammable liquid transport. Foam systems should be designed, installed and maintained to EN 13565-2.

Powder fire protection systems are used in areas where ordinary combustibles, electrical hazards, flammable or combustible materials may be present but which are not normally occupied. Applications include turbines; hydraulic machinery and engines, flammable liquid handling/storage; storage of liquid natural gas. Powder fire protection systems should be designed, installed and maintained to EN 12416-2.

Kitchen fire extinguishing systems are fixed fire extinguishing systems designed for the protection of catering equipment where cooking oil or fat is present, such as cooking appliances and their related extract systems and filters. These systems can be used to protect all commercial cooking equipment and are not just limited to kitchens. Whilst there are no British or European product standards for these products they can be tested and approved to LPS 1223 or UL 300. Industrial fryers are often protected by water mist systems (see DD8489-1 and DD8489-6).

Hypoxic systems are sometimes used to prevent fire occurring in enclosures, such as critical archive storage, where the area is normally unmanned but may be entered for short periods.