Industrial environments across oil & gas, chemicals, mining, manufacturing, wastewater treatment, and energy sectors continue to face persistent risks from hazardous gases. Releases of toxic, flammable, or oxygen-displacing gases such as hydrogen sulfide (H₂S), carbon monoxide (CO), methane (CH₄), ammonia (NH₃), chlorine (Cl₂), and volatile organic compounds (VOCs) can escalate rapidly into life-threatening incidents, operational shutdowns, and large-scale environmental damage. Traditional gas detection approaches, heavily dependent on manual monitoring and portable detectors, are increasingly proving inadequate for modern, complex, and high-risk operations. In this context, autonomous hazardous gas detection systems are emerging as a critical evolution in industrial safety management, offering continuous, intelligent, and self-directed monitoring capabilities that significantly enhance risk control.

Industrial environments across oil & gas, chemicals, mining, manufacturing, wastewater treatment, and energy sectors continue to face persistent risks from hazardous gases. Releases of toxic, flammable, or oxygen-displacing gases such as hydrogen sulfide (H₂S), carbon monoxide (CO), methane (CH₄), ammonia (NH₃), chlorine (Cl₂), and volatile organic compounds (VOCs) can escalate rapidly into life-threatening incidents, operational shutdowns, and large-scale environmental damage. Traditional gas detection approaches, heavily dependent on manual monitoring and portable detectors, are increasingly proving inadequate for modern, complex, and high-risk operations. In this context, autonomous hazardous gas detection systems are emerging as a critical evolution in industrial safety management, offering continuous, intelligent, and self-directed monitoring capabilities that significantly enhance risk control.

Autonomous hazardous gas detection systems are designed to operate with minimal human intervention while continuously sensing, analyzing, and responding to gas hazards in real time. Unlike conventional fixed or portable detectors that require routine manual checks and reactive responses, autonomous systems integrate advanced sensors, embedded intelligence, wireless communication, and automated decision-making protocols. These systems function as a proactive layer of protection, capable of identifying abnormal gas concentrations at an early stage and triggering immediate alerts, shutdowns, or mitigation actions before conditions reach critical thresholds.

At the core of these systems are advanced gas sensing technologies tailored to specific industrial hazards. Electrochemical sensors are widely used for toxic gas detection due to their high sensitivity and selectivity, while infrared (IR) and catalytic bead sensors are commonly deployed for flammable gases. Photoionization detectors (PIDs) play a crucial role in detecting low-level VOCs, especially in chemical and pharmaceutical facilities. Autonomous systems often combine multiple sensor types within a single network, enabling multi-gas detection and cross-verification to reduce false alarms. Sensor self-diagnostics and auto-calibration features further enhance reliability, ensuring consistent performance even in harsh environmental conditions.

One of the defining features of autonomous gas detection systems is their ability to operate as part of a distributed, networked architecture. Fixed detectors, mobile robotic units, drones, and wearable devices can be interconnected through industrial wireless protocols or private networks. This connectivity allows real-time data transmission to centralized control rooms, cloud-based dashboards, or integrated safety management platforms. From a business-to-business perspective, this level of visibility enables safety managers, plant operators, and decision-makers to monitor gas risks across large and geographically dispersed facilities without relying solely on on-site personnel.

Artificial intelligence and data analytics are increasingly embedded within autonomous gas detection platforms, further enhancing their value. Machine learning algorithms can analyze historical gas concentration trends, environmental conditions, and operational data to identify patterns that may indicate developing leaks or process anomalies. Predictive analytics enable early warnings before gas levels exceed permissible exposure limits or lower explosive limits. For industries operating continuous processes, this predictive capability translates into improved uptime, reduced emergency shutdowns, and better asset protection, while significantly lowering the probability of catastrophic incidents.

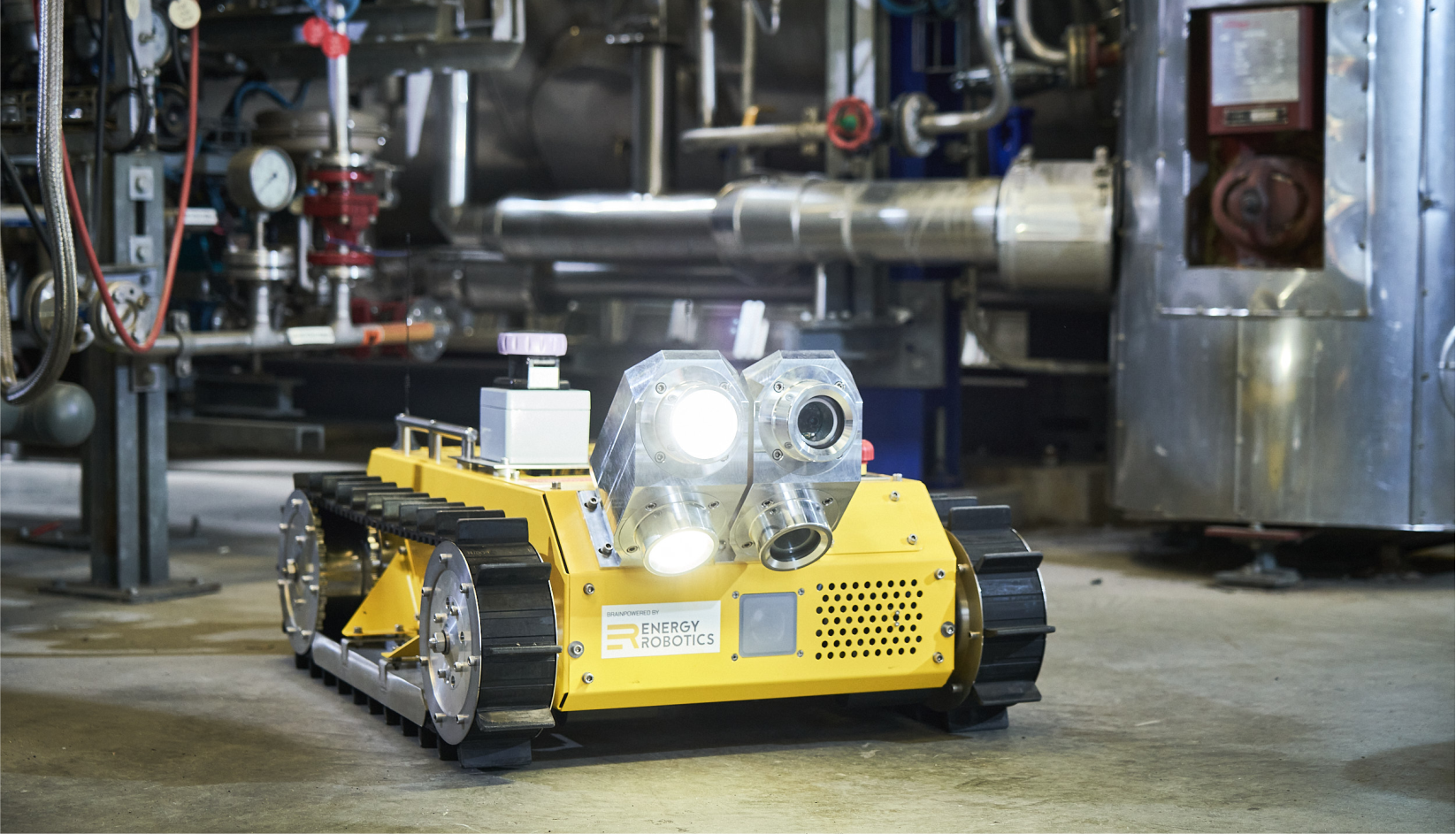

Autonomous mobile platforms represent a particularly transformative application of gas detection technology. Ground-based robots and autonomous drones equipped with gas sensors can navigate confined spaces, offshore platforms, storage tank farms, and disaster-affected zones where human access is limited or unsafe. These systems can conduct routine inspections, leak surveys, and post-incident assessments without exposing workers to hazardous atmospheres. For confined spaces such as sewers, tunnels, silos, and process vessels, autonomous detection eliminates one of the most critical risk factors—initial human entry into unknown atmospheres—thereby aligning strongly with confined space safety regulations and best practices.

Integration with emergency response and process control systems is another key advantage of autonomous gas detection. When dangerous gas levels are detected, systems can automatically activate alarms, ventilation systems, isolation valves, or emergency shutdown procedures. In high-risk facilities, such automation reduces response time to seconds, which is often the difference between a controlled incident and a major accident. From a compliance and liability standpoint, automated responses also demonstrate due diligence and adherence to safety standards, strengthening an organization’s safety governance framework.

Maintenance and lifecycle management of gas detection infrastructure are also being redefined through autonomy. Traditional systems rely on scheduled manual inspections and calibration, which can be resource-intensive and prone to human error. Autonomous systems equipped with self-monitoring capabilities can continuously assess sensor health, battery status, and communication integrity. Maintenance alerts are generated based on actual condition rather than fixed intervals, supporting a shift toward condition-based maintenance. For large industrial operations, this approach reduces downtime, optimizes maintenance resources, and lowers total cost of ownership over the system lifecycle.

From a regulatory and standards perspective, autonomous hazardous gas detection systems support compliance with increasingly stringent occupational health, safety, and environmental requirements. Regulators are placing greater emphasis on continuous monitoring, early detection, and documented response mechanisms. Autonomous systems provide comprehensive data logs, alarm histories, and incident reports that can be used for audits, investigations, and continuous improvement initiatives. For multinational organizations, standardized autonomous systems also help maintain consistent safety performance across multiple sites and jurisdictions.

Beyond compliance and risk reduction, autonomous gas detection systems deliver measurable strategic business benefits. Reduced incident rates lead to fewer lost-time injuries, lower insurance premiums, and minimized legal exposure. Early detection prevents process upsets, product losses, and environmental contamination, protecting both revenue and brand reputation. In capital-intensive industries such as oil & gas and chemicals, the ability to avoid even a single major incident can justify the investment in advanced detection systems many times over. Moreover, organizations that adopt intelligent safety technologies are increasingly viewed as responsible, future-ready partners by clients, investors, and regulators.

In conclusion, autonomous hazardous gas detection systems represent a significant advancement in industrial safety, moving organizations from reactive monitoring to proactive and predictive risk management. By combining advanced sensor technologies, intelligent analytics, autonomous mobility, and system integration, these solutions provide continuous protection in environments where gas hazards pose serious threats to life and operations. For technically driven, business-to-business industries, investing in autonomous gas detection is not merely a technological upgrade but a strategic commitment to safety excellence, operational resilience, and long-term sustainability.