Disaster prevention and preparedness are essential components of maintaining safety and continuity in industrial settings. By implementing robust strategies and protocols, businesses can mitigate risks, minimize the impact of emergencies, and ensure the well-being of employees and assets. This comprehensive guide explores the key principles of disaster prevention and preparedness tailored to industrial environments.

Disaster prevention and preparedness are essential components of maintaining safety and continuity in industrial settings. By implementing robust strategies and protocols, businesses can mitigate risks, minimize the impact of emergencies, and ensure the well-being of employees and assets. This comprehensive guide explores the key principles of disaster prevention and preparedness tailored to industrial environments.

Risk Assessment and Hazard Identification

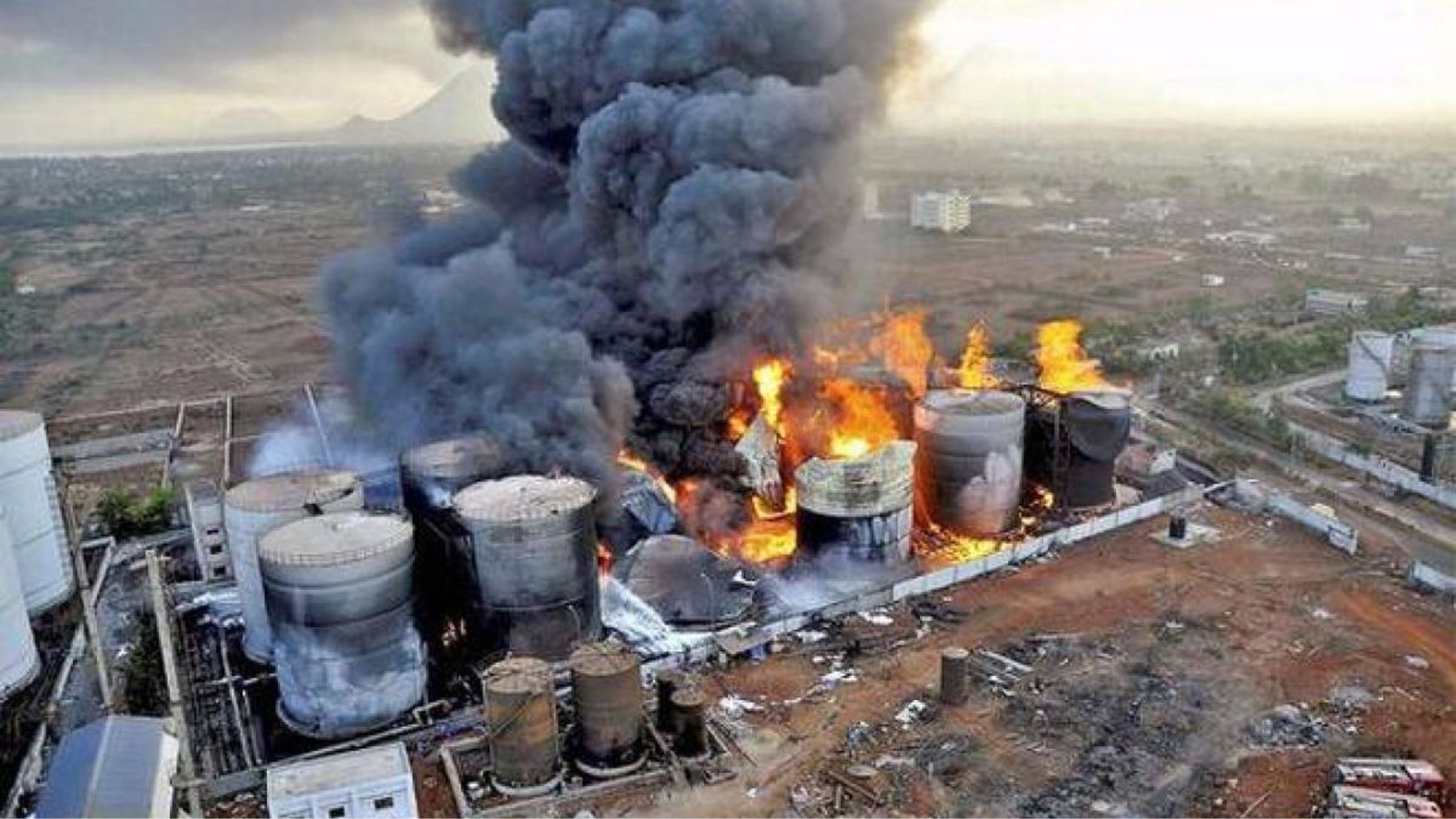

- Comprehensive Risk Assessment: Conduct thorough assessments to identify potential hazards, including natural disasters, industrial accidents, and technological emergencies.

- Hazard Identification: Identify specific risks relevant to industrial operations, such as chemical spills, fires, equipment failures, and structural integrity issues.

Preventive Measures

- Engineering Controls: Implement engineering controls, such as ventilation systems, fire suppression systems, and equipment maintenance protocols, to minimize the likelihood of disasters.

- Administrative Controls: Establish administrative controls, including safety policies, training programs, and emergency response plans, to promote a culture of safety and preparedness among employees.

Emergency Response Planning

Emergency Response Planning

- Development of Plans: Create comprehensive emergency response plans tailored to different scenarios, outlining protocols for evacuation, sheltering, communication, and resource allocation.

- Training and Drills: Conduct regular training sessions and emergency drills to familiarize employees with procedures, enhance coordination, and ensure swift and effective responses during crises.

Resource Allocation and Preparedness

- Stockpiling Essentials: Maintain adequate supplies of emergency essentials, including food, water, medical supplies, and backup power sources, to sustain operations and support employees during disasters.

- Emergency Communication Systems: Implement robust communication systems, such as mass notification platforms and two-way radios, to disseminate alerts, instructions, and updates during emergencies.

Collaboration and Coordination

Collaboration and Coordination

- External Partnerships: Establish partnerships with local authorities, emergency responders, and neighboring businesses to facilitate mutual aid, resource sharing, and coordinated responses to large-scale disasters.

- Interdepartmental Collaboration: Foster collaboration between different departments within the organization to ensure seamless coordination and alignment of efforts in disaster prevention and response.

Continuous Improvement and Evaluation

- Periodic Reviews: Conduct regular reviews and evaluations of emergency plans, procedures, and response capabilities to identify areas for improvement and implement necessary adjustments.

- Lessons Learned: Capture and analyze lessons learned from past incidents and drills to enhance preparedness, address weaknesses, and refine response strategies proactively.

Community Engagement and Outreach

- Community Education: Engage with the local community through outreach programs, workshops, and educational initiatives to raise awareness about disaster preparedness and foster a culture of resilience.

- Public-Private Partnerships: Collaborate with government agencies, non-profit organizations, and community groups to strengthen disaster resilience, share best practices, and enhance overall preparedness efforts.

Disaster prevention and preparedness are paramount in safeguarding industrial facilities, employees, and surrounding communities from potential risks and hazards. By prioritizing risk assessment, preventive measures, emergency planning, and continuous improvement, businesses can build resilience, mitigate vulnerabilities, and ensure a swift and effective response to emergencies, thereby minimizing disruption and promoting safety and stability in industrial settings.