“High voltage” is a relatively arbitrary term, used to refer to electrical energy large enough to cause damage to humans. Various agencies and organizations have their own definition.

“High voltage” is a relatively arbitrary term, used to refer to electrical energy large enough to cause damage to humans. Various agencies and organizations have their own definition.

The International Electrotechnical Commission adopted the following thresholds:

- 1000 Vrms for AC power

- 1500 V for DC power

These may refer to either the potential difference between a high voltage platform and ground or two conducting surfaces of a system. Notice that this does not make any reference to the current or total stored energy in the system…

Where can we find high voltage in the lab?

- Power supplies and power cables

- Capacitor banks

- Certain batteries

- Any electrically conductive surfaces energized by the above

High Voltage Hazards, General Electrical Hazards

High Voltage Hazards, General Electrical Hazards

Electric Shock/ electrocution

Electric shock occurs when sufficient electrical current is able to travel between two conductive surfaces through the body. This typically occurs between an energized surface and the ground but can occur between any two potentials. The risk and severity of the shock depends on a combination of the voltage, current, and frequency (AC or DC.)

Low voltage does not necessarily mean low hazard.

Electric shock may cause burns, damage to muscles, nervous system, and internal tissue damage. Put in context:

- 5 mA is enough to induce reflexive action loss of muscular control. In AC systems this can prevent the victim from being able to let go of an energized surface.

- 75 mA can cause ventricular fibrillation of the heart (a rapid, ineffective heartbeat) and, ultimately, death

- 100 J is enough to stop (or start) a heart.

- 1000 J can blow of entire body parts

Guidelines:

- The conventionally accepted electric shock hazard thresholds are 50 Vrms and 5 mA.1

- Any current above 10 A, regardless of voltage, should be treated as a hazard2

- Stored energy (e.g. in a capacitor bank) greater than 10 Joules should be treated as a hazard2

Because a potential difference is required for current to flow, it is possible with the proper equipment to isolate oneself from the ground (or any other potentials) and perform operations on energized platforms. This is only recommended for highly-trained professionals and does not completely eliminate risk of electrocution.

Burns and fire hazards

Pushing current through any non-superconducting material creates heat. Burns may occur either as a result of skin damage electric shock or due to the conductor being resistively heated to damaging temperatures. Please refer to our pages on fire safety and high-temperature safety for more details.

High voltage operations may also present fire hazards:

- Inappropriate equipment for the needed current may become hot enough to melt or combust nearby material.

- The stored energy in a spark or arc may be sufficient to ignite flammable (or explosive) material.

High Voltage-specific Hazards

Explosion hazards

Stored energy of 10 J or more (or at conditions of V > 250 or I > 500 A) may create arcs, sustained discharges of electricity between conductive surfaces through a dielectric medium (e.g. air). As above, this may be sufficient to ignite combustible or explosive material. This is particularly important if flammable gasses are employed in the system.

X-ray hazards

Electrons accelerated to energies of 20 keV, as in many vacuum systems, create x-rays (x-rays may be created at lower energies, but are typically sufficiently-shielded by the housing equipment.) Additional shielding may be required. For more information see the page on radiation safety (in progress.)

Field Effects

Electric fields associated with high voltage may result in electrical breakdown, free motion of charge through a dielectric medium (commonly air). Unlike in an arc, charge does not need to terminate at a second conductive surface. The discharge created by a tesla coil is one example of electric breakdown. This effect is enhanced at sharp surfaces, such as un-rounded corners or points. As with the above, this may present shock, burn, fire, and explosive hazards.

Personal Protective Equipment

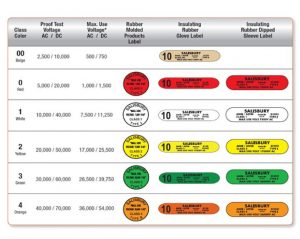

Depending on the application, the following PPE may be advisable:

- Fire-resistant clothing

- Insulated boots (OSHA 1910.136)

- Insulating gloves, mats, and blankets (OSHA 1910.137, OSHA 1926.97)

- Hot stick: Electrically insulated stick (typically fiberglass) with a tool on the end employed for various operations, including testing for high voltage, intentionally grounding conductive surfaces, and even performing certain mechanical operations, depending on the tool.

Laboratory Best Practices

HV Safety Design (and Operation) Rules

The following is taken from a paper by D.C. Fairchild on high voltage and high voltage safety for the CERN particle accelerator school:

The most fallible part of any system is the person operating it. High-voltage safety systems must be design to make them idiot-proof. For regular use it is not acceptable to have safety reliant on an operator correctly following a procedure… It is important that the system is designed in such a way that makes it impossible for an absent-minded operator to hurt themselves or others.”5

Faircloth lays out the following four high voltage design safety rules:

Faircloth lays out the following four high voltage design safety rules:

1. Impossible for to accidentally lock someone in the HV area. In large facilities, this is typically implemented in the form of a “search” system, where the operator must physically disengage various locks and buttons in different regions of the HV area before the HV system can be engaged.

2. Ability to shut down the power inside and outside the HV area (such as an emergency-stop button.)

3. Impossible to power on the HV without locking the area. Interlock switches connected to gates and keys.

4. Impossible to enter the HV area without making it safe. If access to the HV area occurs, all HV platforms should be forcibly grounded. This is particularly important when sizeable capacitors are involved. Just because it's not actively energized does not mean it is safe!

Equipment

The following is applicable to both high and low-voltage systems.

- Only use equipment (cables, terminals, etc.) that is rated for your anticipated usage. Check an amperage chart for what wire gauge is appropriate for your system. (Wikipedia currently maintains a chart based on NFPA 70E.) Bear in mind that these conditions may change with the system environment.

- Fuses, breakers, resistors, and Ground Fault Circuit Interrupters (GCFI) should be used to limit the current through a circuit.

- Regularly inspect cables carrying high voltage for holes, tears, punctures, cuts, or texture changes that may indicate deterioration. Immediately replace any damaged equipment.

- High voltage cables are heavy. Employ proper supports and strain relief.

- Label or mark energized surfaces (even with color-coded tags) this includes labeling of grounded surfaces, when appropriate.

- Use proper insulation to isolate energized equipment and terminals. This may be solid (insulating blocks or shields), liquid (oil–even vegetable oil suffices in a pinch), or gas (SF6).

- Know the breakdown constant of any insulating medium and maintain enough distance between surfaces at different potentials to prevent arcs. For air this is roughly 30 kV/cm

Personnel And Facility Management

- High voltage areas, enclosures, boxes, and cabinets should be labeled with proper signage in accordance with OSHA 1910.

- Equipment at 50 V or greater should be isolated from people and labeled with a warning sign

- Equipment at 600 V or greater should be in complete, insulated, secure, and marked enclosures

- Keep high voltage areas dry and weatherproof.

- Limit access to high voltage areas and operation of high voltage equipment to those with proper training. Multiple tiers of limited or restricted access should be employed when appropriate.

- Maintain a Standard Operating Procedure for all high voltage equipment, especially if multiple users are involved. A checklist is particularly helpful, as even the most experienced users can make mistakes or overlook something.

- High voltage workers should be trained in both CPR and AED use

- Know the location of the nearest AED (often in building hallways near labs)

Fire Safety

While fire safetyis more extensively covered on another page, certain practices relevant to electrical safety listed by UW EHS Fire & Life Safetyare summarized here:

- Eliminate use of extension cords, wherever possible. Restrict to temporary usage.

- Never plug an extension cord into a a relocatable power tap (e.g. power strip)

- Protect any relocatable power taps from environmental hazards (such as fall hazards)

- Keep a minimum of 36 clearance for access to electric panels (in accordance with Fire Code)

- Maintain a clear path of egress. The exit route should be labeled and visible, even following a loss of power.

FIRST AID

Burns and fire-related first aid and emergency response have been covered elsewhere. This section will focus on first aid for victims of electrocution.

When you first encounter a potential victim of electrocution:

- Check for a response without approaching the victim. Your own safety is your first priority. If the source is energized when you touch is, you can also become a victim!

- Prevent access to the hazardous area

- Notify anyone else in the area

- Attempt to rescue the victim by breaking electrical contact with the energized source if it is safe to do so.

- Do not attempt to approach any areas where sparks or other visible electrical activity is present

- First attempt to turn off the source, preferably at a breaker or main. If these are not accessible, remove the plug or shut off the supply

- If there is no safe access to these points, attempt to move the victim with insulating material. Isolate yourself from the ground with plastic or wooden material, or even a phone directory. Attempt to move the victim with a long, insulating object such as a wooden or fiberglass broomstick. Maintain maximum achievable distance between yourself and the victim.

- Once the victim is safe and grounded check for response, including airway, breathing and circulation.

- If trained, perform CPR and use an AED as needed.

- If no urgent condition persists, treat the victim for burns and shock.6

- Lay the person down and elevate their feet above their head, unless head, neck, spinal, broken hip or broken leg bones suspected.

- Keep the person warm, with a blanket if possible (avoiding serious burn injuries)

High Voltage Procedures

In addition to the guidelines associated with general electrical safety and lockout/tagout procedures, there are more stringent safety requirements for high voltage procedures.

The following list provides high-voltage safety tips. For more information, please refer to OSHA Title 29 Section 1910.269 of the Code of Federal Regulations or NFPA 70 (National Electric Code).

- Ensure that only authorized employees work around high voltage equipment.

- Label entrances with a High Voltage Sign.

- Ensure that terminal voltage ratings can withstand surges caused by electrical faults or switching transients.

- Be careful around output circuits even when the input power is off. Parallel power sources and energy storage devices can still be dangerous.

- Be careful when working with power supplies that serve more than one area.

- Before working in a high voltage area, inspect the power supply and check all protective devices.

- Do not work alone near high voltage.

- Label equipment to identify power sources. Label input power sources to identify connected power supply loads.

- Attach emergency shutdown instructions and phone numbers to equipment that is remotely controlled or unattended while energized.

Before entering a power supply or associated equipment enclosure to work on hazardous energy sources, complete the following:

- De-energize the equipment.

- Open and lockout the main input power circuit breaker.

- Check for auxiliary power circuits that could still be energized.

- Inspect automatic shorting devices for proper operation.

- Short the power supply with grounding hooks.